The Frontline Face Shields Project – 50,000 Shields Produced for NHS and Care Staff

There is no doubt that the impact coronavirus has had on the UK has been devastating. With tens of thousands of people admitted to hospital in short succession after the spread of the virus, a shortage of PPE has been one of the most serious risks that the UK’s frontline workers have been up against. Risking their own lives, countless numbers of frontline workers have gone to work without adequate protection. These acts of bravery didn’t go unnoticed by Norfolk man, Colin Breckons.

Colin, who had been furloughed from work as a result of the coronavirus, realised something could be done to help. Colin formulated a plan to help our frontline workers, and as a result, the Frontline Face Shields Project was born.

What is the Frontline Face Shields Project?

In March 2020, Colin began working day and night to produce free PPE for frontline workers. Using his small home 3D printer, he produced dozens of protective face shields and other PPE. The project soon grew and gained the support of over 100 volunteers and help from local businesses. The team went from producing 600 face shields per week to over a thousand shields per day!

However, the project hit a slight snag when volunteers realised there was a huge amount of plastic waste being generated. As a result, the volunteers at Frontline Face Shields sought help from the local community to repurpose this waste.

Max Marriner, one of the volunteers at Frontline Face Shields, comments:

“Our team leader at Frontline Face Shields was very concerned that the 3D printing process was creating a degree of plastic waste which, if properly handled, could provide more vitally important raw material with which to continue the production run (rather than go to landfill)”.

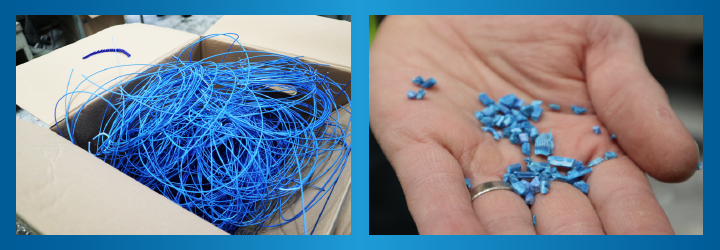

Max adds, “It’s worth noting that in the space of rather less than a fortnight the price per kilo of extruded plastic went from £9 per kilo to nearly £30! I volunteered to find a business that might be able to take our production waste and turn it into 2-3mm chips. These could then be recycled into 3D printer wire”.

Shred Station’s Involvement

But where does Shred Station come into all of this?

Max continues, “My first thought was to approach Shred Station – who I knew of from my days running a charity in Norwich a few years ago. I contacted the team at Rackheath and, in a matter of just a few days, we had a test sample run completed and checked for suitability. It was a complete success. We went for six full transport boxes full of 3D plastic waste which was completed in a matter of hours.”

Shred Station was able to break the plastic waste down through a process called granulation. By using our industrial shredders, we were able to quickly turn boxes of plastic into small 2-3mm pieces. This small size renders pieces suitable for reuse in the 3D printing process.

“The service provided by Shred Station, facilitated by Martin Emms, has been exceptional. Not only have they done this absolutely vital work at speed, but they have also done so at no cost to the project. I think this evidences just how important Shred Station takes its support to the Norfolk community. The project volunteers are hugely grateful to all the team”.

The Frontline Face Shield Project’s Outcome

At the original time of writing, 1st June 2020, the team at Frontline Face shields had made over 17,000 face shields which were delivered to all the major NHS hospitals in Norwich, as well as NHS and private care homes, to GP surgeries, to hospices, to funeral homes and COVID-19 testing sites. By October 2020, this number reached 50,000.

The production and distribution of these pieces of vital PPE have ensured the safety of thousands across East Anglia. We asked Max for a final comment about how he envisages the project’s positive effect on the local community:

“This is making a huge difference to the fight against this dreadful disease and Shred Station is playing a major role in the continuation of the face shield production project.”

The project is now winding down as PPE has become more readily available. We are exceptionally proud to have assisted with the project and will gladly help with any future shredding needs.

If you’d like to learn more about the project, visit the Frontline Face Shields Facebook Page.

Sign up for our newsletter to receive alerts about new blog articles, data protection advice, and Shred Station news.